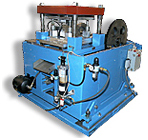

MRF Mechanical Presses

Standard 5 to 100 ton (others available)

Standard 5 to 100 ton (others available)

Guarding removed for ease of viewing.

Maximum Dependability

- Machined to precision tolerances.

- Hardened and ground tool steel draw bars and die rails.

- Heavy duty, fully welded, rigid base.

- Powered by high-torque high-slip Nema D design motor.

- Hydraulic die return shock absorbers.

- Automatic press lubrication system with quick-connect die feed available.

Ease of Operation

- Integrated PLC controls for maximum flexibility and serviceability.

- Includes programmable operator interface that may be used to monitor and/or change system parameters with selectable password protection.

- Designed and built for ease of use and maintenance troubleshooting.

Lower Operating Costs

- Design extends die sharpenings by 10x (based on actual customers’ experience).

- Lower electrical consumption due to large flywheels on MRF mechanical presses.

- Low air consumption due to low volume air clutch and air brake.