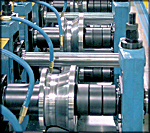

Roll Mills & Roll Formers

Standard 1/2 Inch Diameter to 4 Inch Diameter Spindles Custom Sizes and Spacing Available Where Required

Standard 1/2 Inch Diameter to 4 Inch Diameter Spindles Custom Sizes and Spacing Available Where Required

Guarding removed for ease of viewing.

Greater Accuracy

- Dual precision tapered inboard bearings.

- Precision ground and aligned spindle faces.

- Hardened and ground adjustment mechanisms.

- Heavy-duty hardened, ground gearing & spindles.

- Maximum durability.

- Precision machined main blocks.

- Heavy-duty inboard and outboard stands.

- Lower operating costs.

- Efficient drive train design cuts horsepower needed by up to 50%.

- Automatic gear, bearing and total oil bath lube systems for higher speeds.

Advantages Over Lesser Quality/Competitor Machines

- No roller bearings, only matched sets of taper bearings to lock spindle into location, does not allow for the spindle to “FLOAT”.

- No chain drives to transmit chatter marks onto the finished part, slip, add to power loss and make for difficult tooling adjustments.

- MRF only builds high-quality, precision roll mills for a long lasting, sound investment at an affordable price.